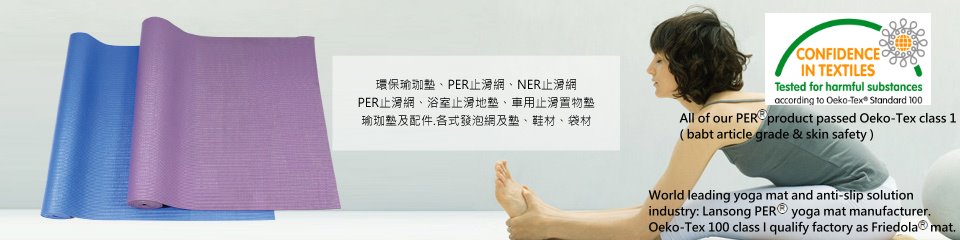

环保PER® 运动瑜珈垫系列

环保PER® 运动滚轮与瑜珈砖系列

冥想运动_身心灵的放松周边产品

环保PER® 止滑网 止滑垫 产品应用

环保PER® 止滑网 止滑垫_网型款式

什么是 PER®?

由PVC成功开发演化成新的环保材质命名为PER®,PER®同样具有PVC的

耐用性及弹性。同时PER®也比PVC多具备了环保优势和健康责任。

因为PVC所含有的有毒物质已于制造过程被撷取出,所以PER®材质已进

化为环保健康材质,而为了让 PER®产品具有PVC的相同功能。我们在

PER®配方中保留了PVC的特性,使PER®具有与PVC相同的功能及外观。

当我方将PER®送测生物可分解检验,送测样品并非仅是检验PER材质本

身,我们是以PER®的完成品进行为期180天的生物可分解测试。因此,

所有的PER®产品是可以通过测试并证明可生物分解及回收利用的。

生物可分解测试:

PER®产品本身是不会进行生物分解的,它必须埋在土壤或是埋于垃圾掩

埋厂后经过细菌的形成进行侵蚀并分解。而为了要达成生物可分解的标

准,测试时间至少需要180天才可完成,而于测试的期间PER®已有30%达

到分解的效果并会持续增加,30%的分解则可达到生物可分解的标准。生

物可分解的检验必须先通过美国ASTM6400产品对环境无害检验才可进行

ISO14855的生物可分解检验,经由两层严格的关卡进行检验,所以你可以

100%信任PER材质所生产的产品。

可回收:

当PER®产品进行回收时是经过特定制程融溶为颗粒状,再经过射出加压形

成另一种产品如箱子,垃圾桶,塑料桶等等。

而为了使PER®产品拥有更加安全的保障,我们已完成符合亚洲及欧美的健

康环保检验认证及测试:

FDA / REACH / ROHS / 重金属 / Oeko-Tex babygrade / NON-6P

耐用性及弹性。同时PER®也比PVC多具备了环保优势和健康责任。

因为PVC所含有的有毒物质已于制造过程被撷取出,所以PER®材质已进

化为环保健康材质,而为了让 PER®产品具有PVC的相同功能。我们在

PER®配方中保留了PVC的特性,使PER®具有与PVC相同的功能及外观。

当我方将PER®送测生物可分解检验,送测样品并非仅是检验PER材质本

身,我们是以PER®的完成品进行为期180天的生物可分解测试。因此,

所有的PER®产品是可以通过测试并证明可生物分解及回收利用的。

生物可分解测试:

PER®产品本身是不会进行生物分解的,它必须埋在土壤或是埋于垃圾掩

埋厂后经过细菌的形成进行侵蚀并分解。而为了要达成生物可分解的标

准,测试时间至少需要180天才可完成,而于测试的期间PER®已有30%达

到分解的效果并会持续增加,30%的分解则可达到生物可分解的标准。生

物可分解的检验必须先通过美国ASTM6400产品对环境无害检验才可进行

ISO14855的生物可分解检验,经由两层严格的关卡进行检验,所以你可以

100%信任PER材质所生产的产品。

可回收:

当PER®产品进行回收时是经过特定制程融溶为颗粒状,再经过射出加压形

成另一种产品如箱子,垃圾桶,塑料桶等等。

而为了使PER®产品拥有更加安全的保障,我们已完成符合亚洲及欧美的健

康环保检验认证及测试:

FDA / REACH / ROHS / 重金属 / Oeko-Tex babygrade / NON-6P

Differences between PVC and PER®

Why PER? Environmental and Health impacts of PVC;

PVC has been found to contain a number of unfriendly chemicals and additives. The manufacturing process alone releases 35 lb/ton of particulate emissions and 17 lb/ton of gas emissions. These are a risk to both human health and the environment.

Toxins:

he most common toxins in PVCs are phthalate plasticizersW and leadW. Phthalate plasticizers have risen a large amount of concern as DEHPW and DINP, the most common phthalates in PVC, have been listed as probable carcinogens by the U.S. Environmental Protection Agency. Studies on animals indicate that the effects of these phthalates may range from gastrointestinal distress to birth defects to various cancers.

Lead can be found in large quantities in PVC and during degradation due to heat and sun exposure, it can be released into the air as dust. Lead has a large range of negative health effects with any sort of human interaction and tends to target the nervous systemW[5].

Finally, dioxin is a byproduct of the manufacturing process of PVC as well as its combustion. It is a Class 1 carcinogen according to the U.S. Environmental Protection Agency and may cause reproductive, developmental, hormone or immune system problems.

Recycling and Biodegradability:

PVC’s provide more negative environmental impacts for their worth when recycling. Due to the large quantities of additives in PVC, they can be cycled a limited number of times and must be sorted out of the recycling process in most cases. They also emit harmful gases including carbon monoxideW, carbon dioxideW and hydrogen chlorideW when melted down and thus extensive harm is caused by their recycling. Due to these challenges only approximately 6.9% of plastics are recycled in the USA. PVC’s are also completely non biodegradable and therefore their environmental impact is negative weather they are being recycled or not.

Material Efficiency:

While PER the production process is no more efficient in material or energy use than PVC, it reigns over in its recyclability and end of life. These two factors contribute to PERs life cycle efficiency as they can be reused more easily than PVC. The embodied energy in PVC products and their material processing is approximately 19000 Btu/lb produced. This does not include the energy requirements for recycling this less re-processable plastic nor the energy required for incineration, which is the only method by which some of this energy may be retrieved.

End of Life:

While PVC incineration may be a more economically viable method of dealing with PVC over switching to environmentally friendly materials, the environmental footprint of this option seems far too large to justify not using alternate options. PVCs may be recycled only a limited number of times and when they can no longer be recycled they will remain in landfills as they do not biodegrade. This issue is exceptionally important to address with PVCs as the leaching of toxins and carcinogens may pose a risk to water quality, air quality and ultimately cause a large amount of human and environmental damage.

Incineration emits a large number of greenhouse and harmful gasses and leaves a large amount of solid waste such as slag, ash and various types of residues.[19] This option may provide some energy, however it is minimal in comparison to the embodied energy in the plastic.

PERs provide an option for end of life that leave little environmental impact. Although they also contribute to landfill space, leaching out of harmful chemicals is not an issue and incineration cause far fewer emissions. PERs also have a much longer life cycle and therefore fewer PER products will reach their end of life in a given amount of time than those made from PVC.

PVC has been found to contain a number of unfriendly chemicals and additives. The manufacturing process alone releases 35 lb/ton of particulate emissions and 17 lb/ton of gas emissions. These are a risk to both human health and the environment.

Toxins:

he most common toxins in PVCs are phthalate plasticizersW and leadW. Phthalate plasticizers have risen a large amount of concern as DEHPW and DINP, the most common phthalates in PVC, have been listed as probable carcinogens by the U.S. Environmental Protection Agency. Studies on animals indicate that the effects of these phthalates may range from gastrointestinal distress to birth defects to various cancers.

Lead can be found in large quantities in PVC and during degradation due to heat and sun exposure, it can be released into the air as dust. Lead has a large range of negative health effects with any sort of human interaction and tends to target the nervous systemW[5].

Finally, dioxin is a byproduct of the manufacturing process of PVC as well as its combustion. It is a Class 1 carcinogen according to the U.S. Environmental Protection Agency and may cause reproductive, developmental, hormone or immune system problems.

Recycling and Biodegradability:

PVC’s provide more negative environmental impacts for their worth when recycling. Due to the large quantities of additives in PVC, they can be cycled a limited number of times and must be sorted out of the recycling process in most cases. They also emit harmful gases including carbon monoxideW, carbon dioxideW and hydrogen chlorideW when melted down and thus extensive harm is caused by their recycling. Due to these challenges only approximately 6.9% of plastics are recycled in the USA. PVC’s are also completely non biodegradable and therefore their environmental impact is negative weather they are being recycled or not.

Material Efficiency:

While PER the production process is no more efficient in material or energy use than PVC, it reigns over in its recyclability and end of life. These two factors contribute to PERs life cycle efficiency as they can be reused more easily than PVC. The embodied energy in PVC products and their material processing is approximately 19000 Btu/lb produced. This does not include the energy requirements for recycling this less re-processable plastic nor the energy required for incineration, which is the only method by which some of this energy may be retrieved.

End of Life:

While PVC incineration may be a more economically viable method of dealing with PVC over switching to environmentally friendly materials, the environmental footprint of this option seems far too large to justify not using alternate options. PVCs may be recycled only a limited number of times and when they can no longer be recycled they will remain in landfills as they do not biodegrade. This issue is exceptionally important to address with PVCs as the leaching of toxins and carcinogens may pose a risk to water quality, air quality and ultimately cause a large amount of human and environmental damage.

Incineration emits a large number of greenhouse and harmful gasses and leaves a large amount of solid waste such as slag, ash and various types of residues.[19] This option may provide some energy, however it is minimal in comparison to the embodied energy in the plastic.

PERs provide an option for end of life that leave little environmental impact. Although they also contribute to landfill space, leaching out of harmful chemicals is not an issue and incineration cause far fewer emissions. PERs also have a much longer life cycle and therefore fewer PER products will reach their end of life in a given amount of time than those made from PVC.

Benefits of PER®

The environmental benefits of using PER over PVC are enormous. Where emissions from PVC production are numerous, PER has little to no harmful emissions even when burned(excluding CO2 which is unavoidable in combustion). PER also does not have any slow emission of toxins and carcinogens, and it is more capable of several recycling cycles. Given that there are fewer harmful additives in PER than PVC it is recyclable without risk of degradation of the recyclate after several cycles. Due to it’s unique composition, recycling PER does not produce the same harmful gases as those produced from recycling PVC.

It is notable that PER does not require phthalate plasticizers in order to achieve the flexibility which is required in many current applications of PVC. Given this fact, it can be seen that the carcinogenic effects are minimized in this way from exposure to carcinogens. Although the filling agents and light stabilizers are not without their threats(occasionally toxic) they remain exponentially more health and environmentally friendly as there are fewer in PER than PVC.

Given all of these benefits, PER is also successful in fulfilling the desirable qualities of PVC. PER is non-slip, water proof and sun protective just as PVC is[12].These qualities allow PER to be a suitable and environmentally friendly replacement for most PVC products.

It is notable that PER does not require phthalate plasticizers in order to achieve the flexibility which is required in many current applications of PVC. Given this fact, it can be seen that the carcinogenic effects are minimized in this way from exposure to carcinogens. Although the filling agents and light stabilizers are not without their threats(occasionally toxic) they remain exponentially more health and environmentally friendly as there are fewer in PER than PVC.

Given all of these benefits, PER is also successful in fulfilling the desirable qualities of PVC. PER is non-slip, water proof and sun protective just as PVC is[12].These qualities allow PER to be a suitable and environmentally friendly replacement for most PVC products.